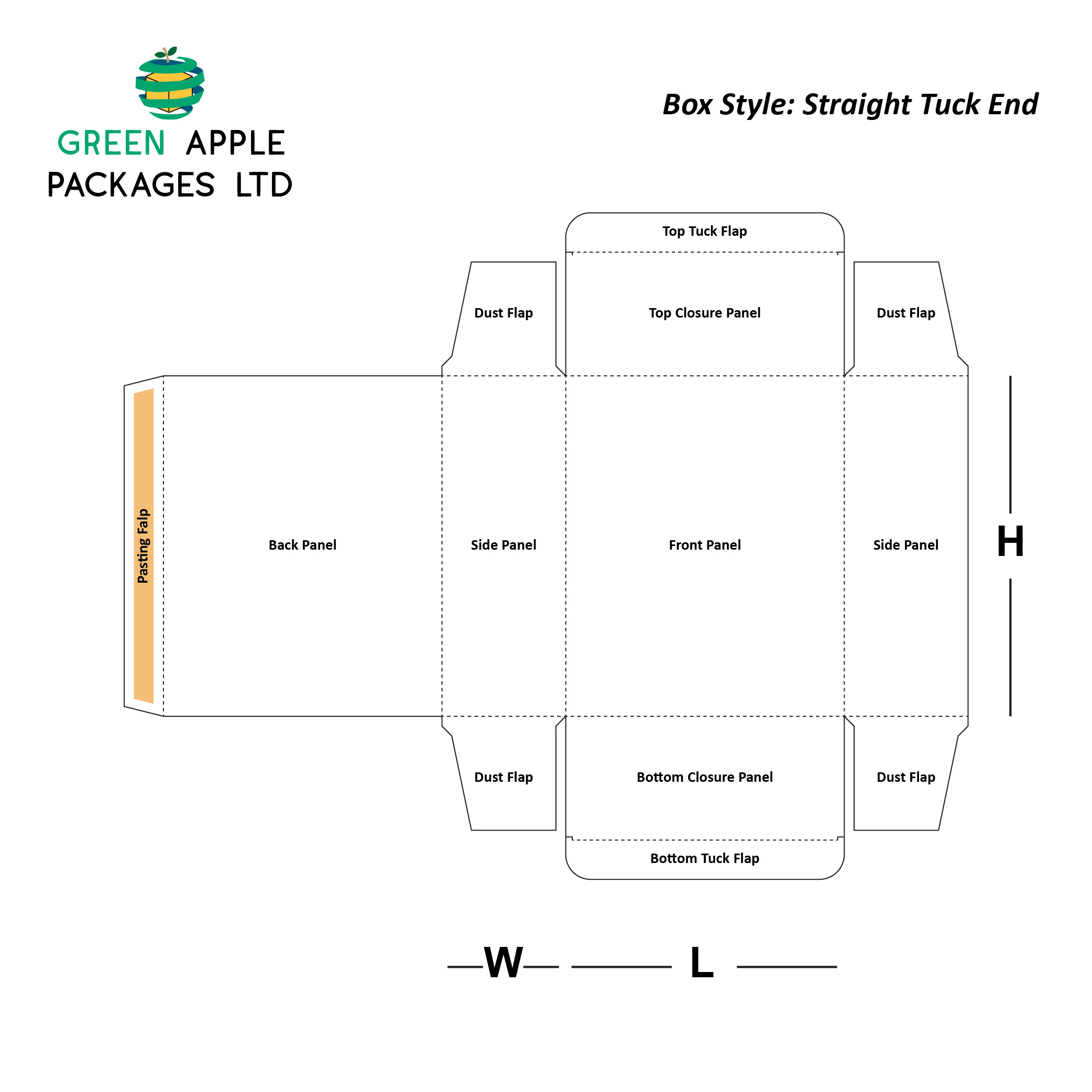

Straight Tuck End

September 1, 2021

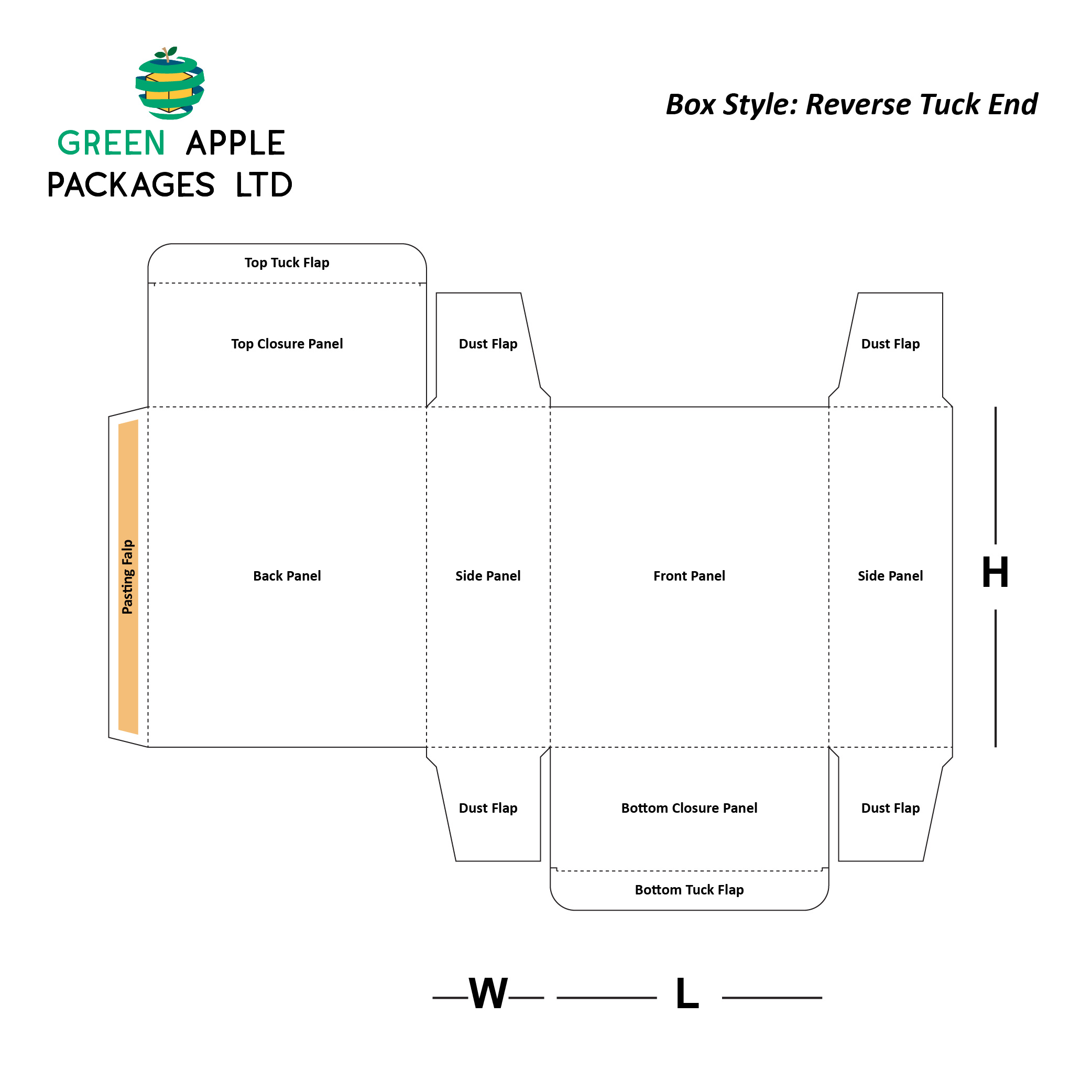

Reverse Tuck End

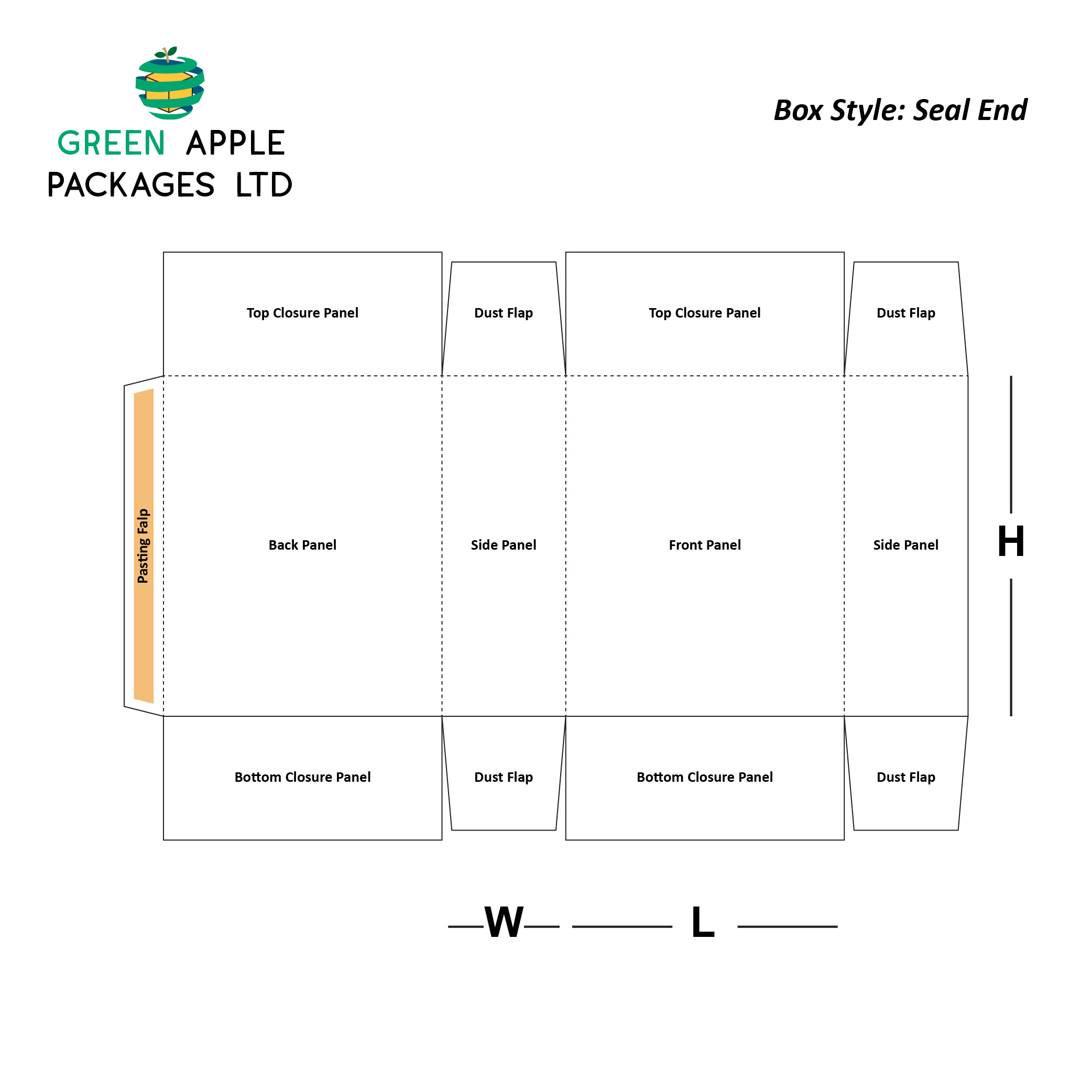

September 1, 2021Seal End

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 4-6 Business Days , Rush |

[caldera_form id=”CF6129ea01c10b9″]

We provide the best possible services of designing, printing, and the choice of material to manufacture the seal end containers for enhanced sales of your business. The true purpose of using boxes is to provide safety for products that are packed in them. One of the greatest innovations in the history of boxes came with the use of seal end containers. These containers consist of a sticky tape on one end that is sealed, and the other end is open, but it can be closed by the use of dust flaps and a top non-removable lid. These boxes have strengthened the features of safety and are made to withstand heavy objects too. The material that is commonly used to manufacture these encasements is Cardboard stock, but Kraft and corrugated sheets can be used to enhance the safety features.

![screen-17.15.28[29.10.2021]](https://greenapplepackages.com/wp-content/uploads/2021/10/screen-17.15.2829.10.2021.png)

Reviews

There are no reviews yet.